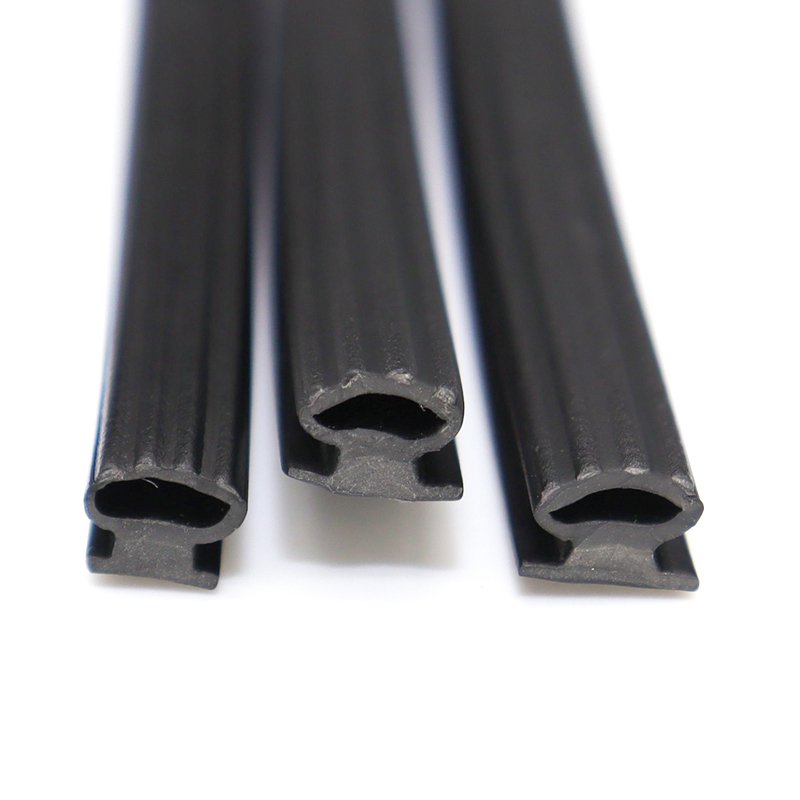

Window Door Seal Weather Stripping

Product Specification

Material: TPE

Hardness: 55shore A

Temperature: -60°C ~+130°C

Color: Black, brown, gray, red, yellow etc

Package: in a roll or according your needs

MOQ: 1000M

TPE (thermoplastic elastomer) door and window seals have many advantages that make them widely used in the construction and manufacturing industries. Here are some of the main features of TPE door and window seals:

Excellent sealing performance: TPE seals can effectively prevent the penetration of air, water and dust, providing a good sealing effect. Thereby improving the energy efficiency and comfort of doors and windows.

Elasticity and durability: TPE has excellent elasticity and can adapt to the opening and closing movement of doors and windows while maintaining a stable sealing effect. Its durability allows it to maintain good performance after long-term use.

Weather resistance and aging resistance: TPE has good tolerance to UV rays, oxidation, moisture and temperature changes, which allows it to maintain performance for a long time in outdoor environments and is not easy to age or deteriorate.

Environmental protection: TPE is an environmentally friendly material that usually does not contain harmful substances. It can be recycled and is environmentally friendly.

Good processing performance: TPE material can be formed through thermoplastic processing technology, allowing it to meet complex design requirements and high precision during the manufacturing process.

Comfort: The softness and elasticity of TPE seals provide better sealing, avoiding noise or vibration issues that may be caused by traditional materials.

Low maintenance costs: Due to the durability and anti-aging properties of TPE materials, doors and windows using this seal usually require less maintenance and replacement, reducing long-term costs.

TPE door and window seals are widely used in the following fields:

Residential buildings: used in home doors and windows to improve energy efficiency and comfort.

Commercial buildings: in doors and windows of offices and shops, to improve sound insulation and dustproofing.

Industrial facilities: used in doors and windows of factories and warehouses, providing strong durability and protection.

Automotive industry: used in car doors and windows, to increase sealing and reduce noise.

Ships and vehicles: in doors and windows of ships and other vehicles, to resist environmental damage.

TPE door and window seals can be installed in multiple parts of doors and windows to ensure sealing and improve overall performance.

1. Door frame edge

The seal is installed on the inner or outer edge of the door frame. The seal fits tightly with the door frame to form a sealing band. It can effectively prevent the penetration of air, dust and moisture, and improve the sealing and sound insulation of the door.

2. Window frame edge

The sealing strip is installed on the edge of the window frame, fitting the opening part of the window, and ensuring that the gap between the window frame and the window is completely sealed. It can reduce heat loss and noise, and improve the thermal insulation and sealing of the window.

3. Door and window joints

The sealing strip is installed at the joints between the door and the window to fill the gap between the joints. It can ensure that the gap does not leak air when the door and window are opened and closed, and improve the airtightness.

4. Door and window bottom

The sealing strip is laid along the bottom of the door or window, usually in a long strip, covering the entire bottom edge. It can prevent the entry of dust, insects and moisture, and is suitable for the bottom of the exterior door or window.

5. Opening edge

The sealing strip fits the edge of the hinged or sliding door and window, and may adopt a U-shaped or D-shaped design. Reduce the noise when opening and closing the door and window, and improve the sealing effect.

6. The gap between the frame and the wall

The sealing strip fills the gap between the door and window frame and the wall. It can improve sound insulation and thermal insulation and avoid energy loss.