The differences and common points between fumed silicone rubber and mixed silicone rubber?

The differences and common points between fumed silicone rubber and mixed silicone rubber?

Many friends who use silicone sealing strips often have strict requirements on product quality, especially those used in the food industry and machinery industry. Next, I will briefly explain to you how to choose high-quality silicone rubber materials.

The difference,

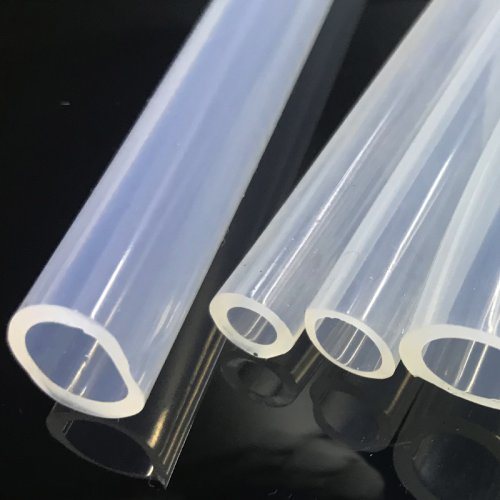

Generally, fumed silicone rubber have higher transparency. The transparency of mixed silicone rubber may vary depending on product formulas and additives, and may generally not be as transparent as fumed silicone rubber.

Fumed silicone rubber usually have high tensile strength and good tensile properties. They will not deform or turn white when stretched permanently. The tensile strength of mixed silicone rubber may vary due to different product formulas and processing techniques. It will turn white after stretching, and will deform after long-term high-intensity stretching.

In terms of use, fumed silicone rubber products may have a longer life than silica gel compound rubber products.

Commons,

1. They all have excellent high and low temperature resistance and can be used for a long time in a temperature range of -50°C to 250°C;

2. They all have excellent chemical stability and are not prone to chemical reactions with acid, alkali and salt substances;

3. It has the characteristics of non-toxic and tasteless, and can fully reach the food.

4. The hardness are same, and the commonly used hardness is between 40 duro and 80 duro.